Who are we?

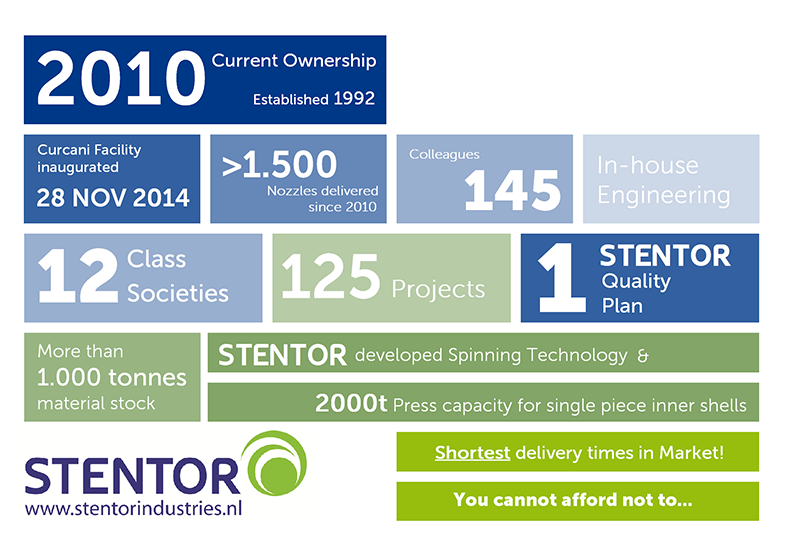

Stentor Industries BV is a Dutch/Romanian company with a fully certified -ISO 9001:2015, ISO 14001:2015 and ISO 3834-2:2005- production facility located in Romania. Since 1992 Stentor has specialized in quality steel constructions applied in maritime propulsion systems and in heavy-duty industries. Nozzles, thruster-tunnels and rudders are some of the core products supplied to the maritime customers. Mining and demolition components are examples of products manufactured for heavy-duty applications.

With in-house Engineering and Quality Assurance, Stentor is well equipped to work on a wide range of steel constructions. Stentor has gained experience in catering to customer’s specific needs, through years of supplying certified components made from carbon, stainless, high-strength and wear resistant steels. State of the art equipment, comprehensive stock levels as well as an experienced and certified workforce, guarantee quality results, on time, at a competitive price.